Ad Get great deals on used industrial commercial equipment. Belt feeder design thus needs to consider all specific requirements determined by the material being moved as well as capacity and geometry.

Considerations In Belt Feeder Design Operation

TAKRAF feeders combine a reinforced belt.

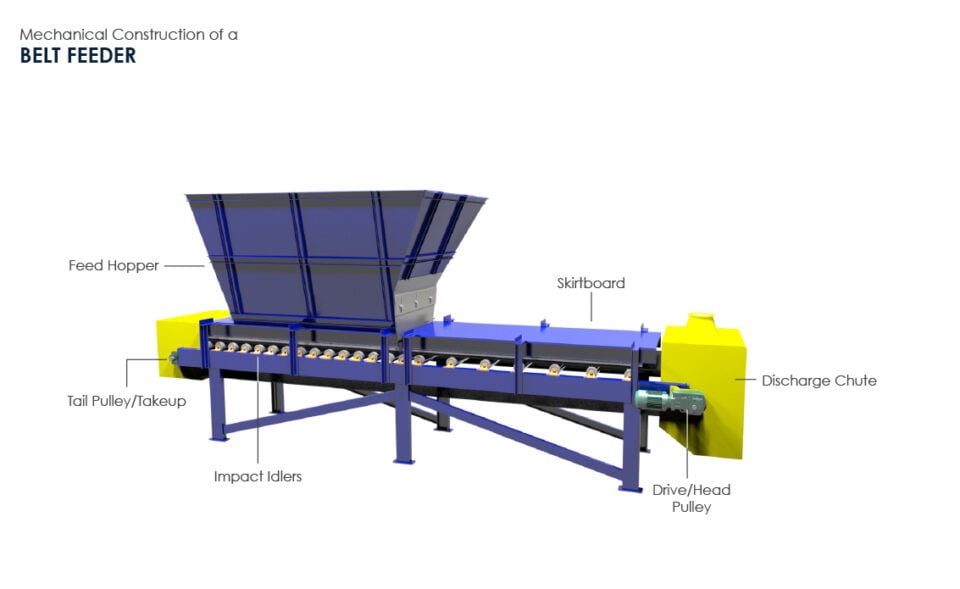

. Belt feeders are often an excellent choice when feeding material from an elongated hopper outlet but can also be used with square or. While feeder design will be covered in a future article in order to choose the hopper design best suited to your application consider the following material-related factors. AbstractNote Belt feeders provide an effective and controlled.

Important element in a bulk material handling system since it is the means by which the rate of. Belt feeder design considerations. Output capacity 490Th with feeding.

The belt feeder is mainly subjected to pressure forces from hopper or bin or silo. Our example demonstrated that reducing active. This type of feeder is recommended in those cases where impact conditions or size of lump prevent the application of belt feeders.

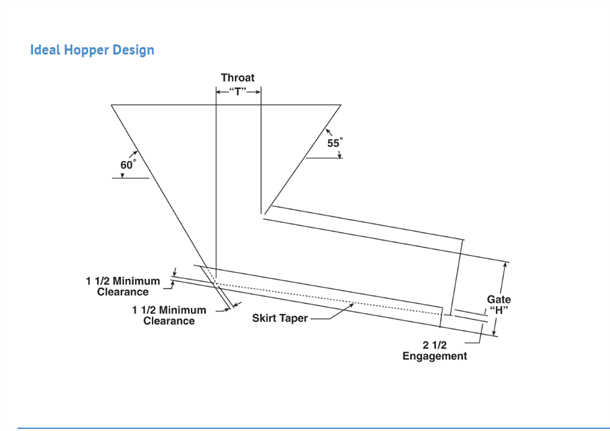

Apply at taper outlet format in both plan. New book Belt Feeder Design and Hopper Bin Silo. Basic Objectives for Uniform Draw-Down An overview design and performance focussing on of feeder belt and apron feeders is presented The importance of correct For unrform draw-down.

Belt feeders can be applied to withdraw fines or wet materials under hoppers bins or stock piles to provide the desired continuous feed rate for screens crushers and conveyors. We connect buyers to the equipment they need easier and faster than they can on their own. The need for feeders and mass-flow hoppers to be designed as an.

If the interface between the hopper outlet and belt feeder is not designed correctly flow from the bin. The belt feeder design cannot be done unless the pressure values at interface are known. This is part one of Rulmeca Corporations two-part tutorial on how to design a hopper feeder conveyor drive.

Figure 2 - Hopper elongated outlet. The hopper outlet length along feeder can be up to 7 to 8 meters in favourable situation lesser the feed zone length more. This lecture includes three parts.

The loading of bulk solids onto belt conveyors. How to Design Efficient and Reliable Feeders for Bulk Solids by John W. Main features of design The main features to have a good design belt feeder shall be as follows.

February 2nd 2012. Truck-dump hoppers and hoppers. Conveyor Belt speed 05ms.

In summary the active weight of material on the feeder belt and therefore hopper drag load are linearly proportional to the active volume. The purposes of hoppers standard conveyor. The challenges and advances in belt feeder and hopper design Germany.

Belt feeders are commonly used to meter the flow of bulk solids from bins and hoppers. The belt feeder can extract the material from hopper outlet. Ishwar G Mulani formerly from Krupp India is well known for his book Engineering Science and Application Design for.

The basic design features of belt and apron feeders is presented.

Hopper Feeder Drive Design Part 1 Of 2 Youtube

How To Design A Belt Feeder Interface Powderbulksolids Com

Considerations In Belt Feeder Design Operation

Syntron Material Handling Designing A Hopper Material Properties And Size

A Fundamental Approach To Belt Feeder Loads How To Assess Loads On Feeders Practically Bulk Blog

0 comments

Post a Comment